Welcome to OTTO JUNKER Group

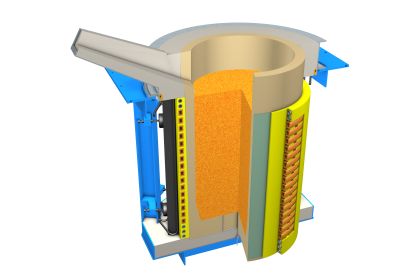

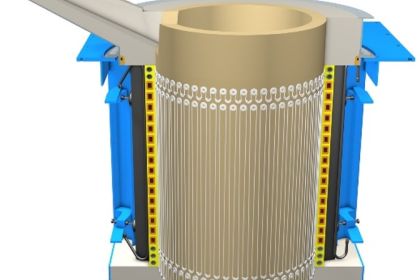

the world's leading provider of industrial furnace systems for melting, heat treatment and recycling

The name OTTO JUNKER stands for first-class capital goods. The plant engineering product program for the cast iron / steel, light and heavy metal industries covers the entire process chain from melting plants to heat treatment plants.

We aim to further expand our market success through a high level of technical expertise, a consistent quality policy and the ability to solve very demanding tasks.

We strive for leadership regarding innovative technology for the benefit of our customers and offer our employees safe jobs with room for advance.

We are a fair partner for our suppliers. Consistent increase in value and continuous growth are the basis of our entrepreneurial activities for the benefit of the owner.

News & Publications

Download.

Find out more.

You want to find out more about OTTO JUNKER? Here we provide you with all relevant content to download with a click. Can’t find a document? Contact us.

Compliance & ESG

Compliance - doing the right thing

At the OTTO JUNKER Group of Companies, compliance and integrity are inextricably linked with business, because we are convinced that long-term success can only be achieved by responsible conduct. This means that we observe the law, comply with accepted standards such as the UN principles for business and human rights and act based upon shared values.

Trust, credibility and reliability - our company values are the foundation of our business activities and of our day-to-day interaction.

Employer qualities

Become a part of the OTTO JUNKER family and of our success story

At OTTO JUNKER, challenging and exciting tasks and a family working environment with flat hierarchies await you.

Our benefits cover flexible working times and vacation models, attractive remuneration and bonuses, professional training, individual personnel development and talent promotion, health care and joint activities such as running clubs and regular company events.

As a future-oriented long-established company, we build on long-term relationships. We attach great importance to the compatibility between family and work and offer you a secure job with a future-oriented perspective.

BECOME A PART OF OUR TEAM

Career with Otto Junker!

Whether you are just beginning your professional career or are already an experienced pro - we offer you exciting career opportunities to match your talent and experience.

Our career portal offers you a wide range of opportunities to develop your potential in a future-oriented and innovative company. We are looking forward to meeting you and to being successful together!

Phone +49 2473 601-0

+49 2473 601-0

E-Mail info@otto-junker.com

info@otto-junker.com