Benefits at a glance:

- Furnaces with protective gas atmosphere and hydrogen operation

- Excellent temperature uniformity across the entire strip width

- Reproducible production results

- Continuous operation

- Furnace bypass for exclusive degreasing and pickling operation

Apart from strip flotation furnaces, vertical furnace systems are used for handling large strip thicknesses or a high hydrogen content in the protective gas. Apart from that, OTTO JUNKER is your innovative partner in the modernization of existing vertical furnaces.

OTTO JUNKER offers comprehensive solutions providing not only the furnace - the core component - which is developed and manufactured in-house, but also all the associated elements such as:

Key components include:

- Coilers with coil cars, belt wrappers, and automatic sleeve loading

- Shears

- Strip joining systems

- Cleaning and degreasing stages

- Brushing machines for cleaning and surface treatment

- Flood or spray pickling

- Passivation chambers

- Strip storage towers

- Vertical furnaces up to 1,000 °C, gas or electrically heated

- Protective gas operation "HN lean" and "HN rich" with up to 100% hydrogen

This comprehensive approach ensures that the customers receive a system precisely tailored to their individual product range. In-house development and design guarantee precise harmony among the system’s individual components, contributing to improved product quality.

Global references confirm that significant performance improvements are possible with new OTTO JUNKER technology, both in existing installations and in third-party equipment.

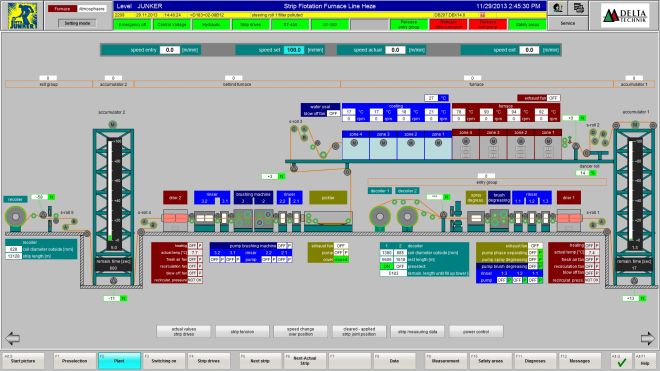

Automation Technology

Reliability and ease of operation are essential for high product quality at maximum throughputs. OTTO JUNKER systems benefit from decades of commissioning experience, which is taken into account in software, hardware and automation technology of each new system.

- Schematic images in visualization provide information about the production process and the function of system components at any time.

- Continuous recording of process data for quality monitoring.

- Integration into higher-level IT systems (Level 3).

| strip thickness | 0.03 - 4 mm |

| strip width | 300 - 1,300 mm |

| temperature | up to 1,000°C |

| strip speeds | up to 120 m/min |

Downloads

Phone +49 2473 601-0

+49 2473 601-0

E-Mail sales@otto-junker.com

sales@otto-junker.com