All plants

Find your desired plant

Filter - applications

Filter - application/process

Filter - atmosphere

Filter - types of heating

Filter - metals

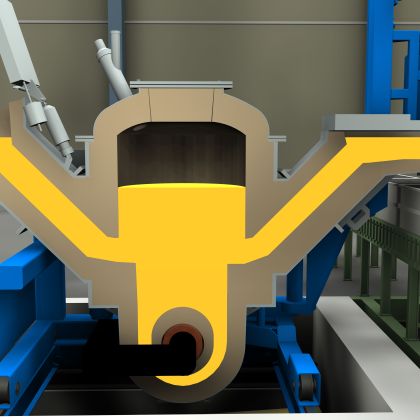

Coreless induction furnace

Induction melting technology enables the efficient, CO2-neutral melting of metals with the shortest melting times and selectively controllable movement of the liquid melt.

Learn more

Pressurized pouring furnace

This pressurized pouring furnace, equipped with a rod-and-nozzle stopper assembly, is perfectly suited for automatic sand casting lines where it ensures precise and virtually slag-free pouring.

Learn more

Channel type holding furnace

These channel-type furnaces are highly efficient holding units for large quantities of molten metal. They can be used to decouple the casting and melting processes and provide operators the flexibility to maximize the use of off-peak electricity.

Learn more

OTTO JUNKER stainless steel foundry

The products of our OTTO JUNKER stainless steel foundry - castings made of high-alloy materials - can be found on the OTTO JUNKER CM GmbH websit

Learn more

INDUGA Induction Furnaces

The subsidiary of OTTO JUNKER GmbH specializes in Channel melting furnaces, holding and casting furnaces for copper alloys and aluminum, automatic tilting casting device PUMA pouring machine, steel strip coating furnaces, Plasma heating for ladles and casting tundishes.

Learn more

Billet Heaters

Adaptable and energy-efficient billet heating systems designed for press shops, storage facilities, saws, bolt quenching, and handling equipment.

Learn more

Pusher type furnace for pre-heating and homogenizing

Pusher-type furnaces are used for preheating and homogenizing of rolling ingots in continuous operation.

Learn more

Cartridge furnace for pre-heating and homogenizing of rolling ingots

Cartridge furnaces are used for preheating and homogenizing of rolling ingots, particularly for small lot sizes.

Learn more

Chamber type furnace for homogenization

Chamber furnaces for homogenizing and stress-relieving rolling slabs are used in producing hard alloys of the 2xxx and 7xxx series, especially for aerospace applications.

Learn more

Soaking pit furnace for pre-heating and homogenizing

Pit furnaces are designed to provide direct reheating or homogenizing of their slab charge.

Learn more

Continuous homogenizing furnace

To achieve high throughput capacities, continuous furnaces are employed for the homogenization of bars.

Learn more

Horizontal heat treatment line

Heat treatment lines for aluminum plates are precision-manufactured in strict adherence to aerospace industry specifications, specifically meeting the rigorous standards set by AMS 2750 E and AMS 2772 C for the heat treatment of aluminum alloys.

Learn more

Strip flotation furnace for the heat treatment of strips

Strip flotation lines are employed for the horizontal heat treatment of aluminum strips, mainly for the automotive and aerospace industries.

Learn more

High convection chamber-type furnaces for the annealing of strip coils

Strip coil furnaces are employed for the intermediate and final annealing as well as tempering of aluminum strip coils.

Learn more

Massflow Chamber type furnace and cooling chamber

Chamber furnaces for heat treatment of aluminum foil coils are used for degreasing and annealing of foil coils of different thicknesses.

Learn more

Solution heat treatment plant

This type of furnace is specifically designed for solution annealing, quenching and artificial aging of wheels made of cast aluminum.

Learn more

Roller hearth furnace for tube, Brass rod, wire, profile

OTTO JUNKER roller hearth furnaces operate on the proven principle of high convection.

Learn more

Strip processing line, Annealing and Pickling line with horizontal flotation furnace

OTTO JUNKER strip treatment lines for degreasing, annealing, and pickling cover the entire product- and alloy range

Learn more

Strip processing line, Annealing and Pickling line with vertical annealing furnace

Vertical furnace systems are used when dealing with large strip thicknesses or a high hydrogen content in the protective gas.

Learn more

Degreasing and Pickling lines, finish-brushing and passivation

The degreasing process is of utmost importance for the quality of the annealed strip because even low oil or emulsion residues on the strip surface can cause unwanted surface discolorations and, thus, loss in quality.

Learn more

Hot Dip Tinning line

Since 1989, OTTO JUNKER has been a global leader in the design, development, and installation of hot-dip tinning systems, with a specific emphasis on serving the international connector market.

Learn more

Flotation dryer for coated silicon steel strip

The system is integrated into an ACL (Annealing and Coating Line) and is designed for the continuous and horizontal operation of drying painted electrical steel strips.

Learn more

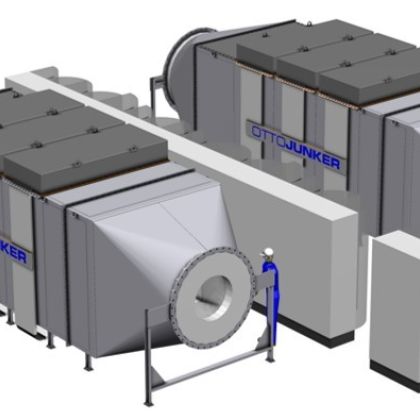

Scrap Recycling

Aluminum recycling is the future. However, the recycling process entails CO2-intensive procedures. Achieving a carbon-free circular economy requires the implementation of environmentally friendly solutions for the recycling process.

Learn more

Battery recycling furnace

The most advanced recycling processes for batteries from electromobility necessitate thermal procedures. Otto Junker provides solutions for treating entire battery modules as well as intermediate products in the recycling process.

Learn more

Power to Heat Energy storage

Otto Junker designs highly efficient Power-to-Heat systems for the direct utilization of green energy. In the industrial sector, 60% of the deployed primary energy is converted into heat.

Learn more