INDUGA is a subsidiary of OTTO JUNKER GmbH and specializes in Channel melting furnaces, holding and casting furnaces for copper alloys and aluminum, automatic tilting casting device PUMA pouring machine, steel strip coating furnaces, Plasma heating for ladles and casting tundishes.

They offer a range of equipment, including but not limited to:

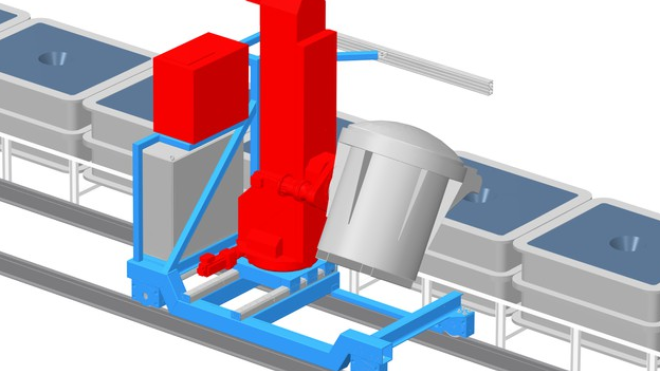

Form and series casting plant PUMA pouring machine

Channel melting furnaces

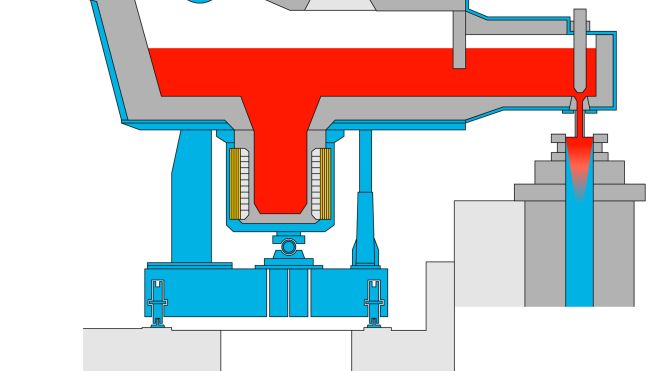

Low-pressure casting plants

Vertical continuous casting furnaces

Horizontal continuous casting furnaces

Chip melters

Drum furnaces

Strip coating kettles

Piece coating kettles

Pre-melters

Cathode melters

Plasma technology

Casting furnace Indumat

Low-pressure casting plant in sand casting

Storage furnace for aluminum

Alloy furnaces

Further information on induga.com

Phone +49 2473 601-0

+49 2473 601-0

E-Mail sales@otto-junker.com

sales@otto-junker.com