Melting

Filter - applications

Filter - application/process

Filter - atmosphere

Filter - types of heating

Filter - metals

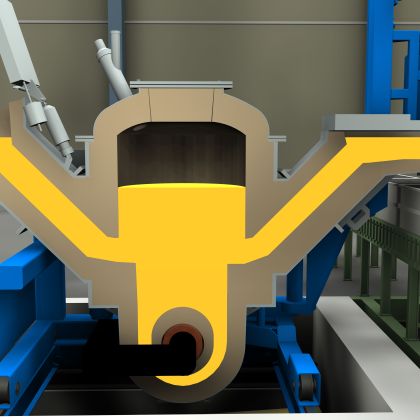

Coreless induction furnace

Induction melting technology enables the efficient, CO2-neutral melting of metals with the shortest melting times and selectively controllable movement of the liquid melt.

Learn more

Pressurized pouring furnace

This pressurized pouring furnace, equipped with a rod-and-nozzle stopper assembly, is perfectly suited for automatic sand casting lines where it ensures precise and virtually slag-free pouring.

Learn more

Channel type holding furnace

These channel-type furnaces are highly efficient holding units for large quantities of molten metal. They can be used to decouple the casting and melting processes and provide operators the flexibility to maximize the use of off-peak electricity.

Learn more

OTTO JUNKER stainless steel foundry

The products of our OTTO JUNKER stainless steel foundry - castings made of high-alloy materials - can be found on the OTTO JUNKER CM GmbH websit

Learn more

INDUGA Induction Furnaces

The subsidiary of OTTO JUNKER GmbH specializes in Channel melting furnaces, holding and casting furnaces for copper alloys and aluminum, automatic tilting casting device PUMA pouring machine, steel strip coating furnaces, Plasma heating for ladles and casting tundishes.

Learn more